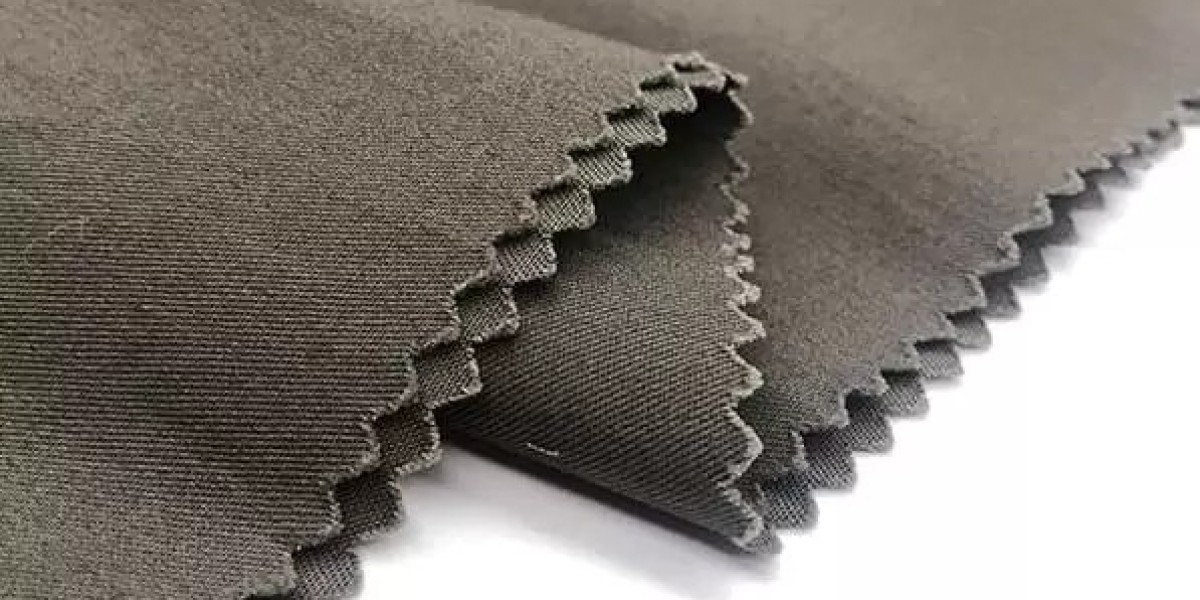

What are the testing methods for Twill fabric? Twill fabric is a commonly used fabric for outdoor items such as tents and bags. Twill fabric has a variety of testing methods, and the small edition only gives a brief introduction to the most commonly used and most accurate testing methods.

At present, the most commonly used Twill fabric testing methods at home and abroad mainly include the American Society for Testing Materials standard water vapor pouring cup method and the Japanese industrial standard testing method.

All coated or laminated fabric is secured to the support frame with rubber rings and the coated or laminated surface faces outward. The installation of the sample support system is based on the ability to float in a tank with a temperature of 23 ° C. After testing the test cup mass (including sample, desiccant, and film) with the film facing upward, quickly turn the test cup upside down and place it in the sample support rack. The assembly is placed in a constant temperature 30 ° C ±2 ° C device. After 15min, take the test cup out of the thermostat, turn it upside down and measure its weight. The above is the most practical method for Twill fabric testing at home and abroad. Most of the Twill fabric tested by these test methods can achieve the effect of waterproof and moist-proof.

The United States has been in a leading position in the waterproof fabric industry, and the country's market is also very large, the test data of the method is relatively high, and the astm standard naturally becomes the most commonly used method. Now most customers use this method for testing. The fabric to be tested is covered with a permeable cup containing distilled water, fixed and inverted, weighed with a top-loading balance with an accuracy of 0.001g, and placed in the position of the wind tunnel row. The temperature and relative humidity of the environment are recorded before the cup is weighed in an environmental chamber with a temperature of 23 ° C, relative humidity of 50% and wind speed of 2.5m/s. The weight of each cup and the time it was weighed were recorded. The weight at 3h, 6h, 9h, 13h, 23h, 26h and 30h was recorded, and the water vapor transfer speed was calculated using the formula wvt=24*△m/(s*t). The average of the six samples is used as the result of the test, and the average multiplied by 24 is converted to the result in g/m2*24h.

Twill fabric https://www.yongshuntextile.com/product/Cotton-Fabric/Twill-fabric/